120 Machine Manual

This section of the Aagard Machine Manual provides a pictorial and written description of each servo reference point on the machine. For each section of the machine, a table lists the servo number, name and values for each servo. Each servo drive is shown pictured in its referenced position with a visible mark or reference indicator for a quick visual check. When the servo drive has been referenced, this mark/indicator should give the operator a quick visual confirmation that the drive has been referenced properly. This is not intended to replace the use of a tape measure, squares, or other means to check reference positions. It is intended to allow operators to quickly check the reference position of a drive without the use of any tools, and continue on with minimal downtime. See the Reference page on the HMI for more information regarding servo reference positions.

Servo # |

Servo Name |

Direction of Positive Movement |

Reference Position |

End Position |

Reference Mark Location |

|---|---|---|---|---|---|

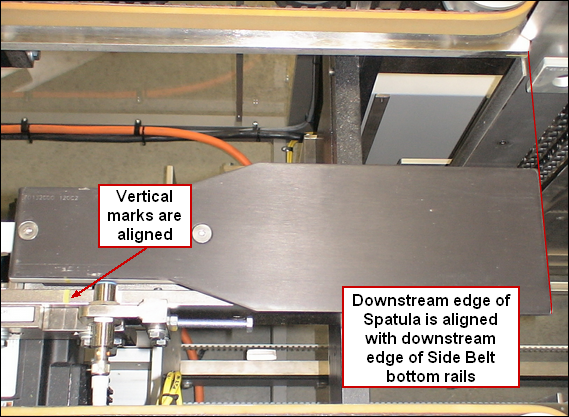

1 |

Toward downstacker flights |

0.25 |

0 |

Downstream edge of spatula is at the shear point. (Downstream edge of side belt bottom rails) |

|

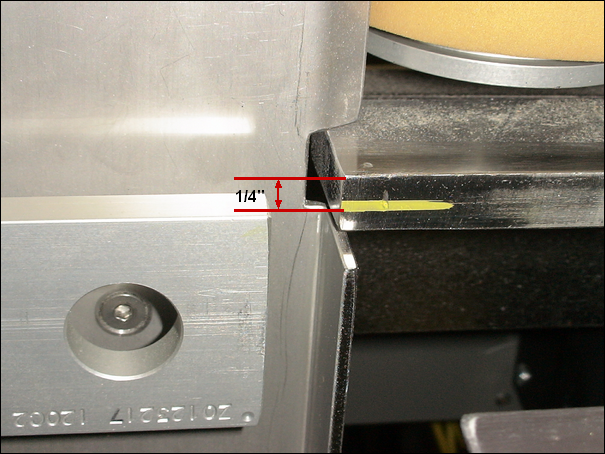

2 |

Down with product |

-24.375 |

0 |

Top of flight 1/4" below sheer point |

|

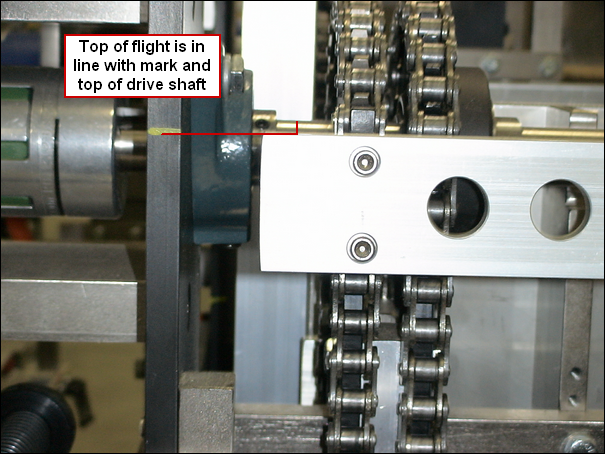

3 |

Down with product |

-24.375 |

30.95 |

Top of flight in line with the top of upper drive shaft |

|

4 |

Down with product |

-19 |

0 |

Top of flight 1/4" below sheer point |

|

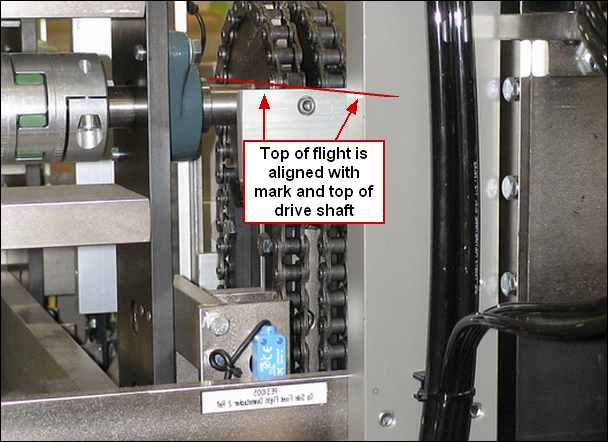

5 |

Down with product |

-18.875 |

30.827 |

Top of flight in line with the top of upper drive shaft |

|

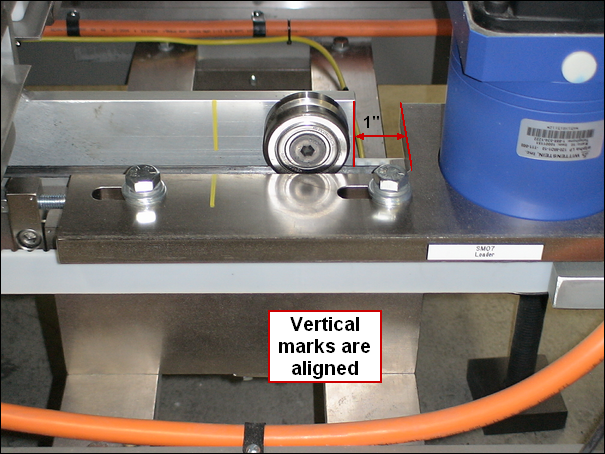

6 |

Moving product downstream |

-1 |

0 |

1" off of upstream hardstop (Located on upstream end of v-rail) |

|

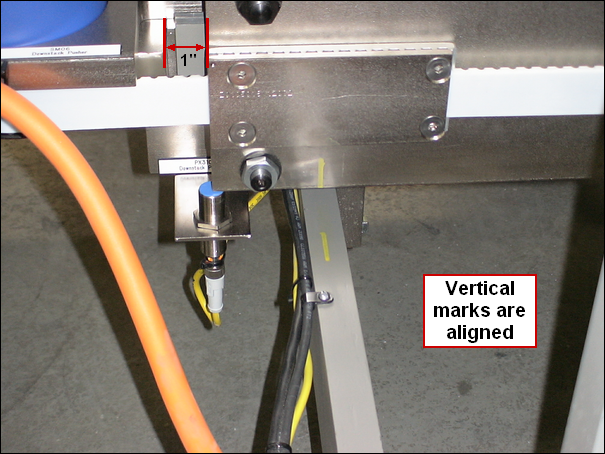

7 |

Moving product downstream |

-1 |

0 |

1" from the mechanical stop in the retracted position |

|

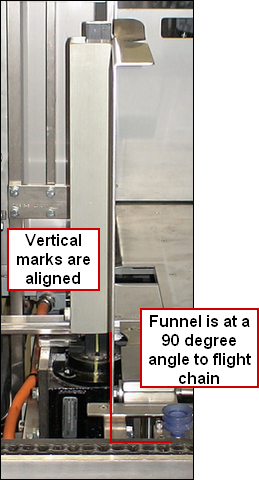

8 |

Funnel moving out of case |

-10 |

0 |

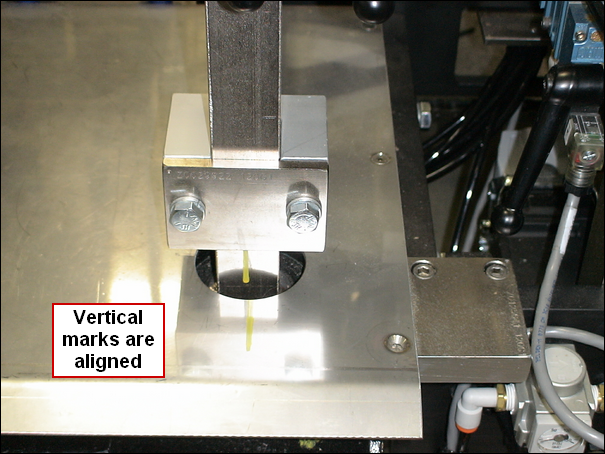

Funnel is 90 degrees to flight chain |

|

9 |

Funnel moving out of case |

-15 |

0 |

Funnel is 90 degrees to flight chain |

|

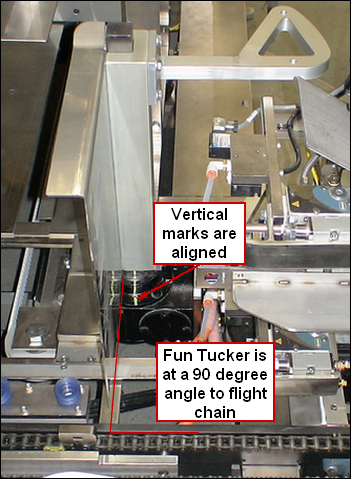

10 |

Tucking trailing flap |

-5 |

0 |

Tucker arm is 90 degrees to flight chain |

|

11 |

Tucking leading flap |

140 |

0 |

Tucker arm is 90 degrees to flight chain |

|

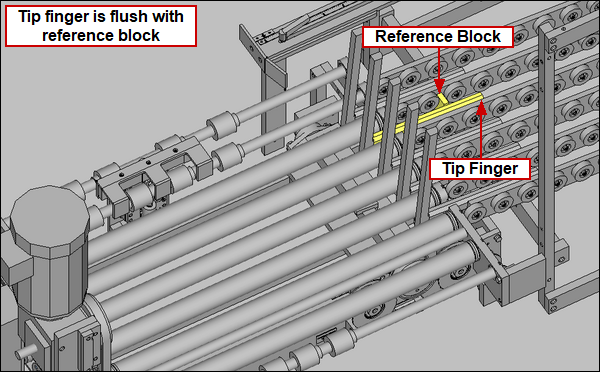

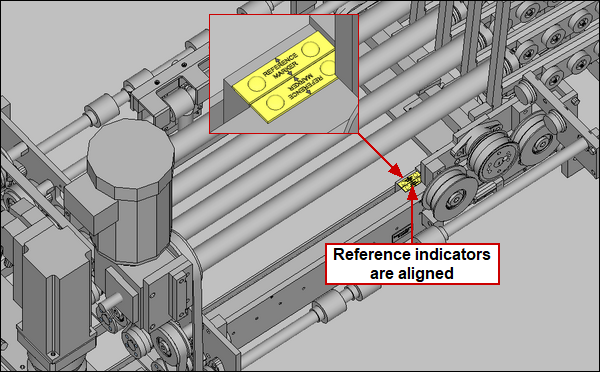

12 |

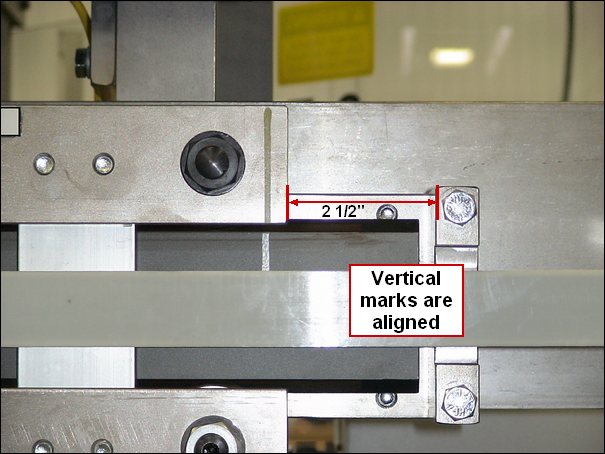

Toward palletizer |

34.53 |

32 |

2.5" from the downstream mechanical stop |

|

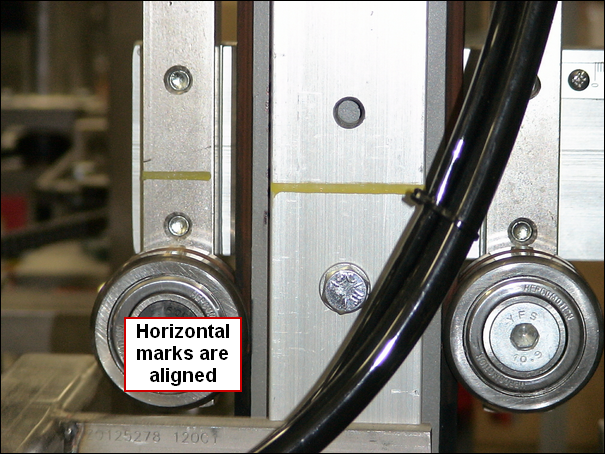

13 |

Down |

-1 |

0 |

1" from the mechanical stop in the retracted position |

|

14 |

Toward palletizer |

0.675 |

0 |

Leading edge of flight is aligned with fixed side of load chamber |

|

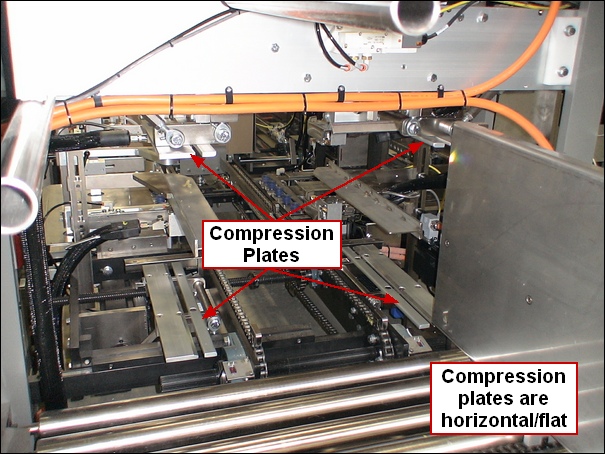

15 |

From horizontal to vertical |

-4 |

0 |

Compression plate is horizontal (open) |

|

16 |

From horizontal to vertical |

-2 |

0 |

Compression plate is horizontal (open) |

|

17 |

From horizontal to vertical |

-8 |

0 |

Compression plate is horizontal (open) |

|

18 |

From horizontal to vertical |

-3 |

0 |

Compression plate is horizontal (open) |

|

19 |

Moving towards operator side |

-7.625 |

0 |

Operator side face of flight is aligned with operator side of sheet metal backstop |

|

20 |

Tipping product |

-1 |

0 |

1 inch from the "up" mechanical stop |

|

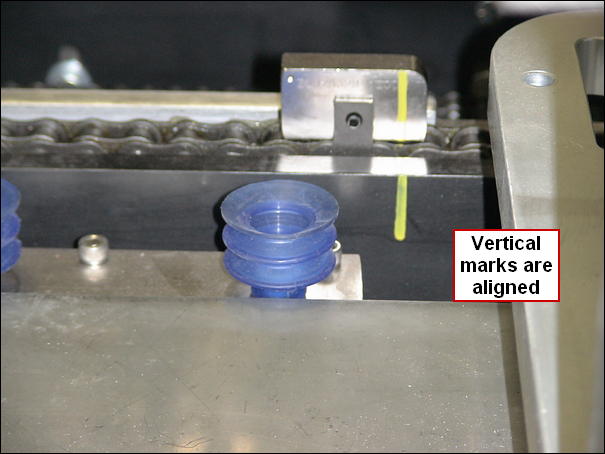

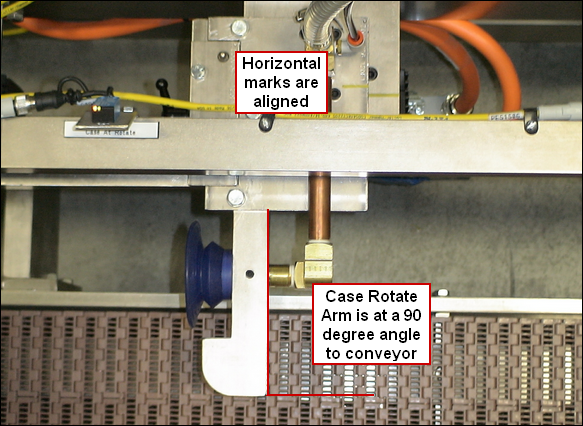

21 |

Turning case |

130 |

0 |

Vacuum cup arm is 90 degrees to conveyor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|